Design your own acoustic solution

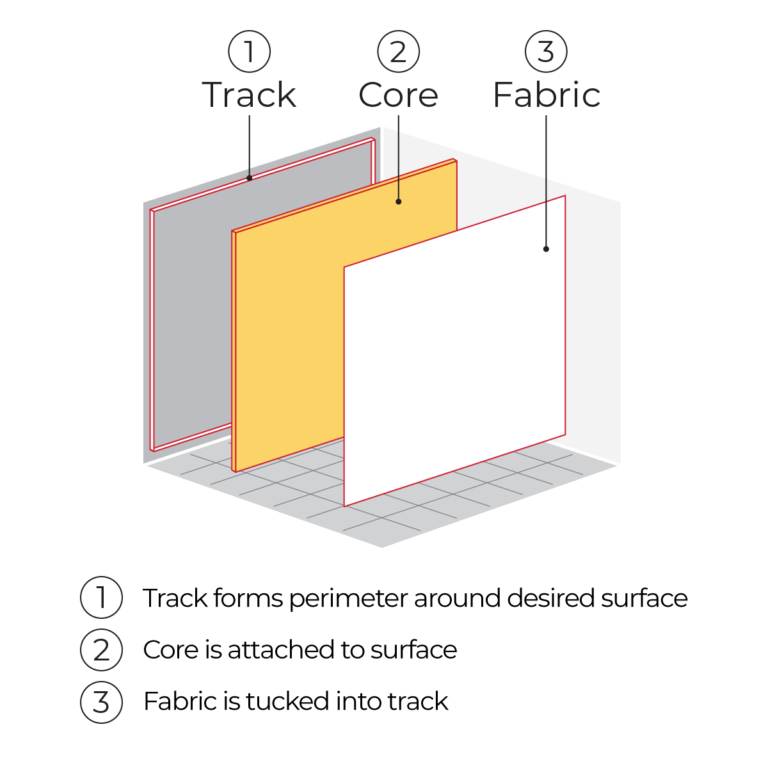

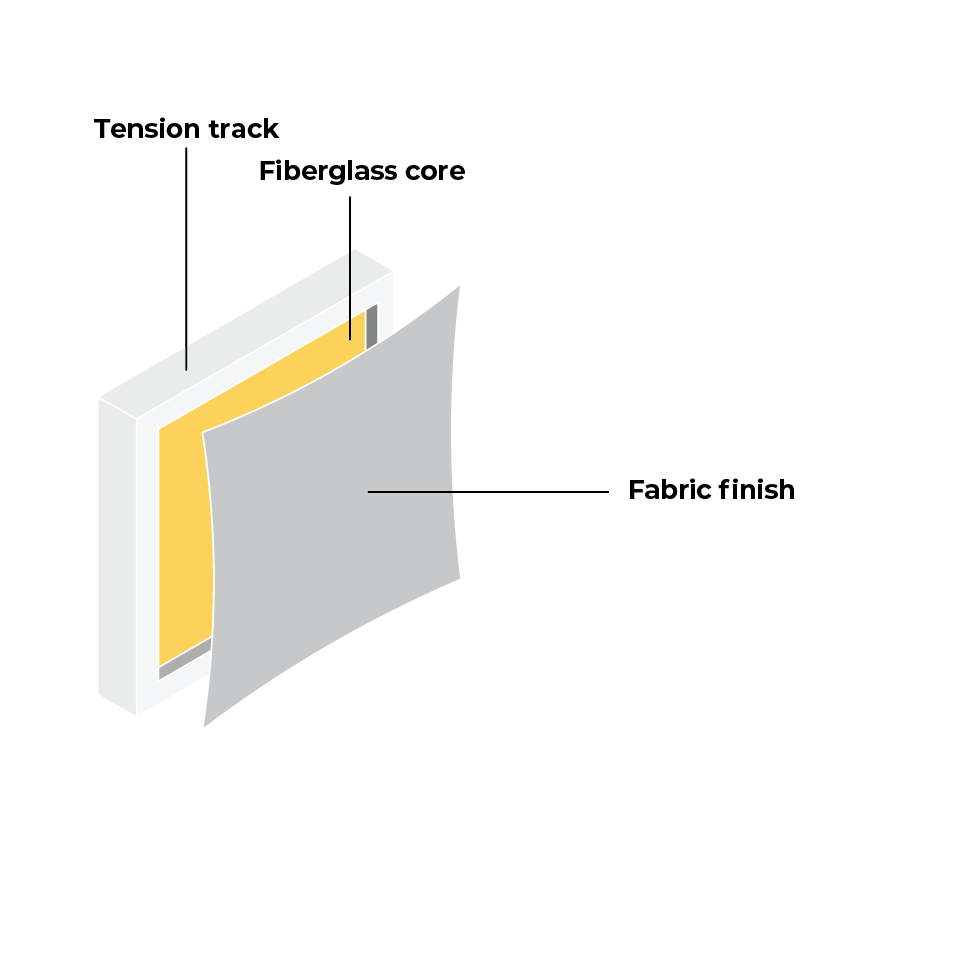

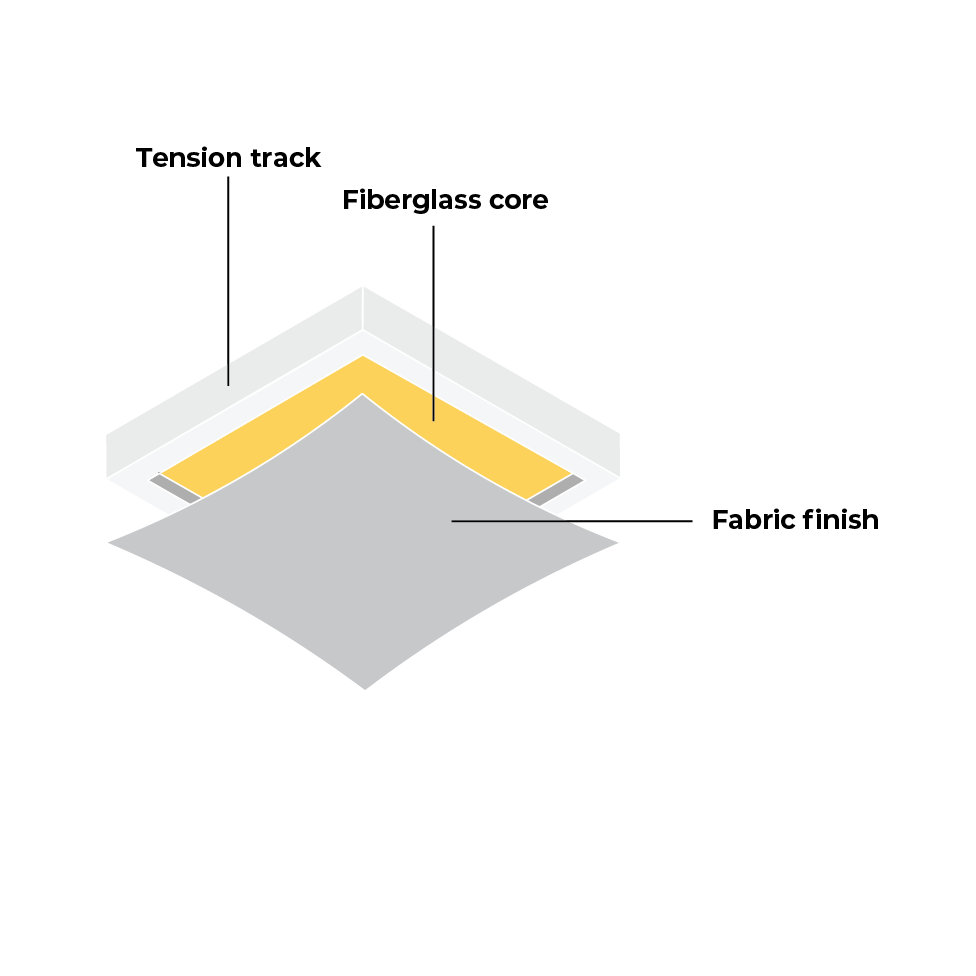

Eurospan is not a singular product like a panel. It is a set of tools and materials that can create custom acoustical surfaces, skipping the traditional finishing steps of a drywall surface.

Eurospan still gets the same performance and uses the same core as all other Conwed products. You can even use NAF core for LEED projects.

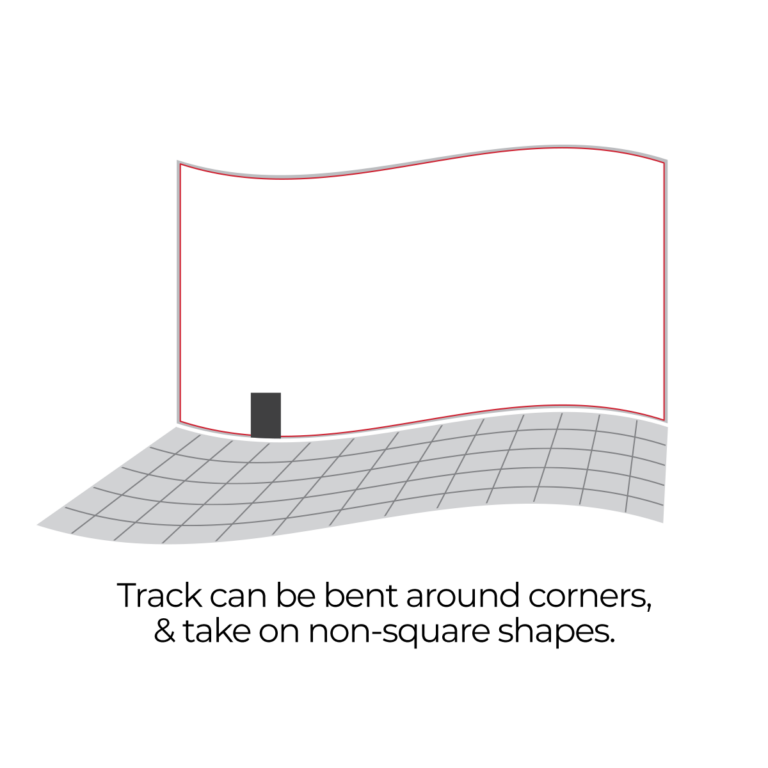

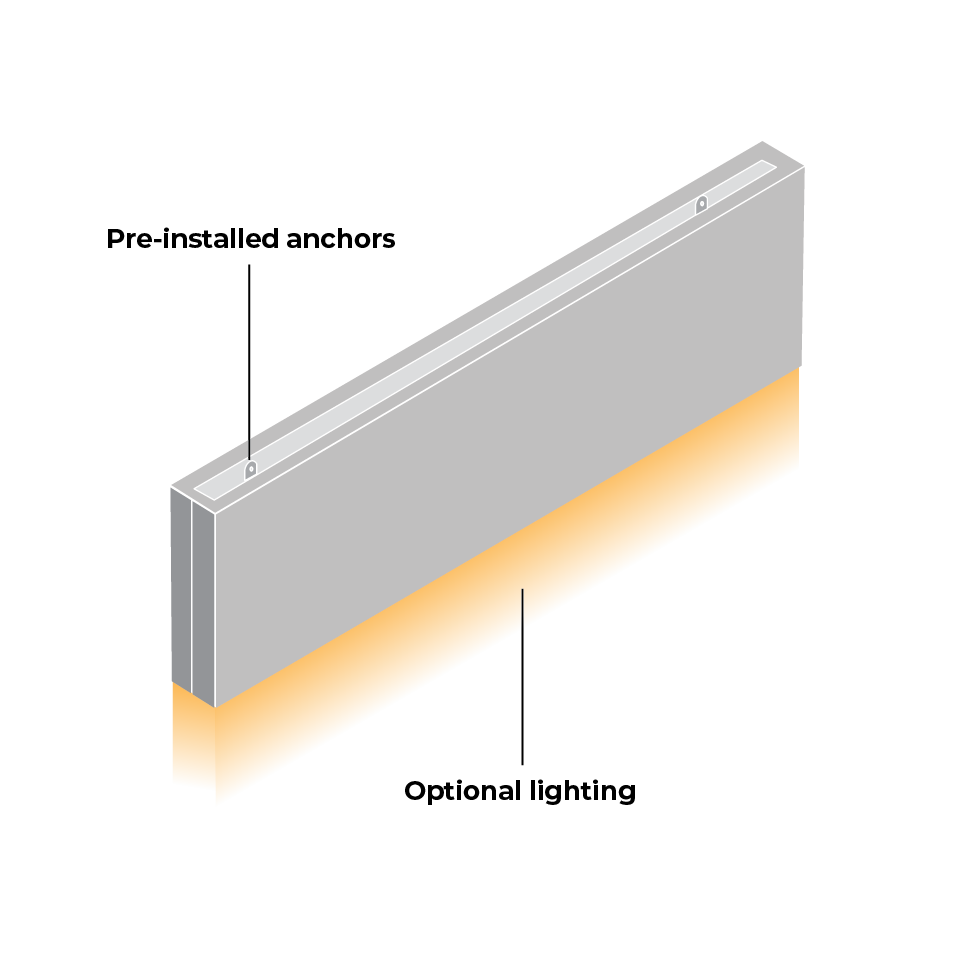

Extrusions are a piece of cake with Eurospan. The system is so easy to work with it’s actually preferred over a normal drywall install for those that have worked with it.

The Eurospan system can be completely discrete, or stand out, depending on which of the thousands of compatible fabrics you choose.

Yes, Eurospan is compatible with thousands of fabrics, but not ALL. For a reliable installation that will stay taught, things like all-wool textiles should be avoided. If you're not sure if your finish is compatible, shoot us an email and we'll check our records or do a test ourselves if we haven't tried it already.

Eurospan finishes are a textile engineered to be the ideal finish for the system. Easy to work with, carefully selected shades of popular colors, and ready for custom dyeing.

If you have something truly eye-catching in mind, we can print images directly onto your fabric finish. DPI : 300 recommended.

1445 Holland Rd

Maumee, OH 43537