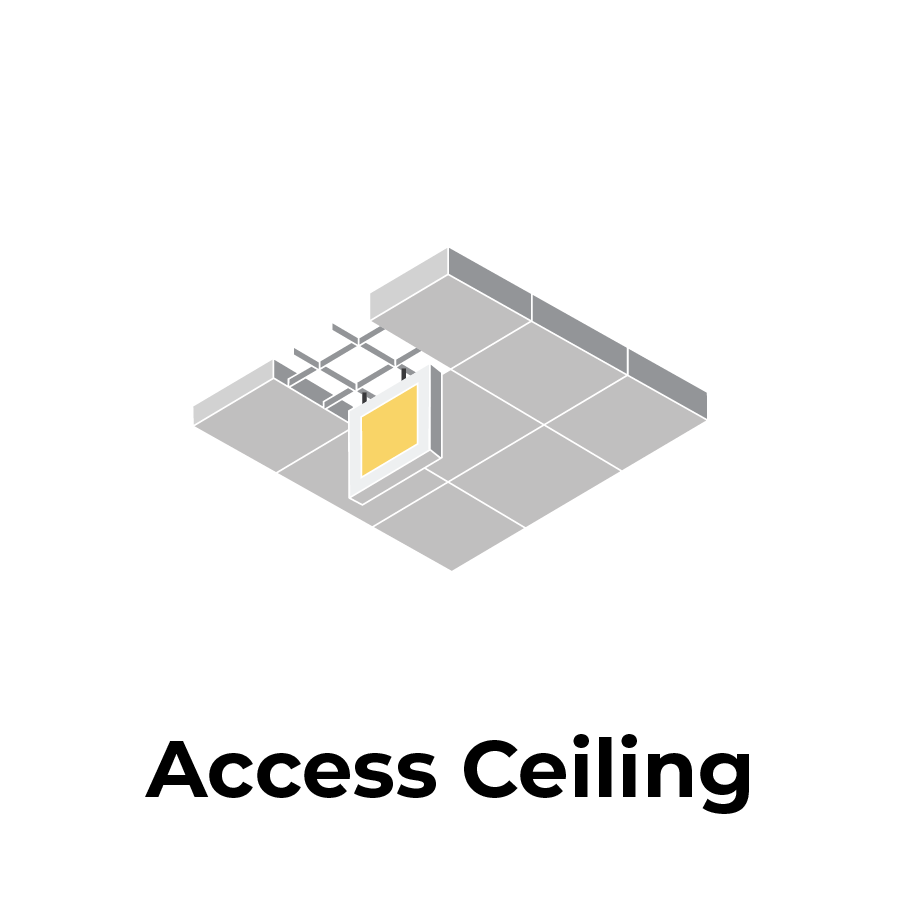

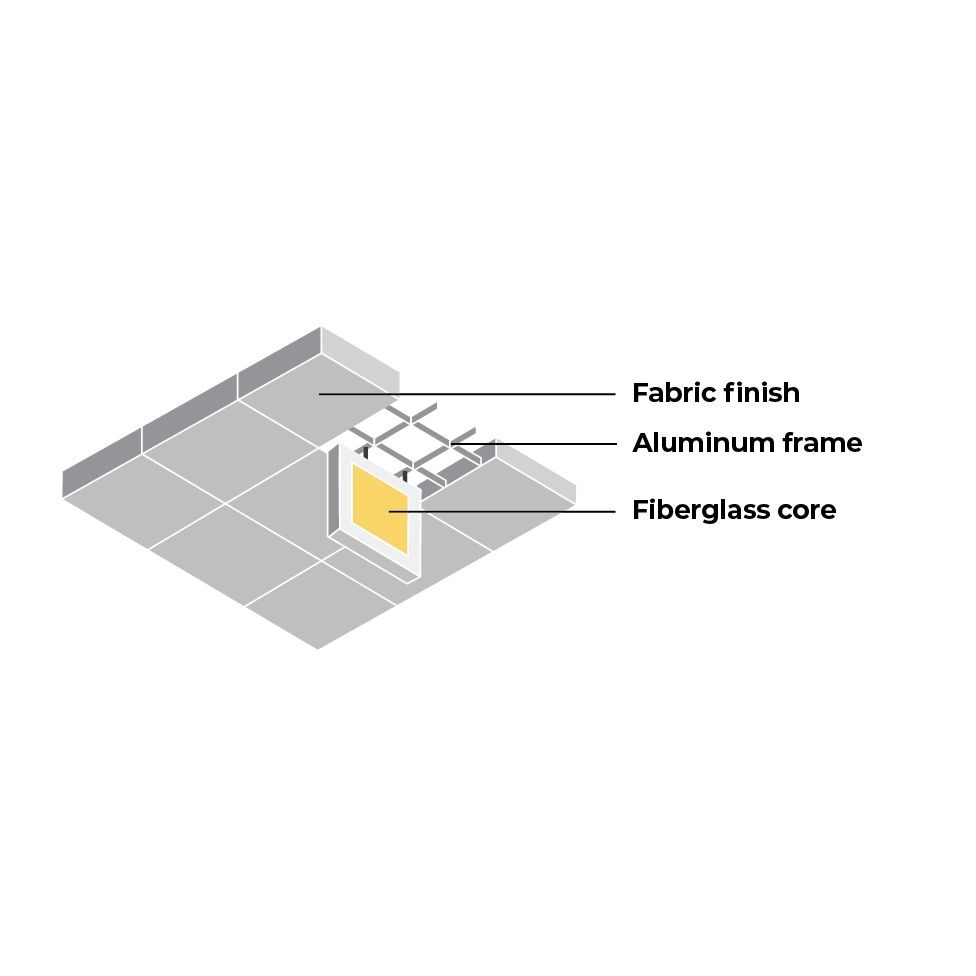

Access Ceiling

Skip the reading & just give me the data

Field modification documents

Install guide

Marketing

Access gets its name from its easy-to-use downward hinged access panels. Access shines in large spaces where access to mechanical equipment, network trays, and electrical is needed on a regular basis.

NRC range

0.90"

Core thickness range

1 1/8"

Edge profile

Slight Bevel

Mounting options

Torsion spring mounting, extruded aluminum grid mains and V-shaped spacer bars.